Understanding changes in industrial process heat consents

Join our on-demand webinar to find out how changes to the Resource Management Act (RMA) will affect your business

Let’s be honest — keeping up with regulatory changes can feel like a full-time job, especially when they could impact the way your business runs. If your operations rely on industrial process heat devices, then the recent changes to New Zealand’s Resource Management Act (RMA) are something you’ll want to pay attention to. The consenting process can be challenging, but understanding what’s happening and how it affects you doesn’t have to be overwhelming.

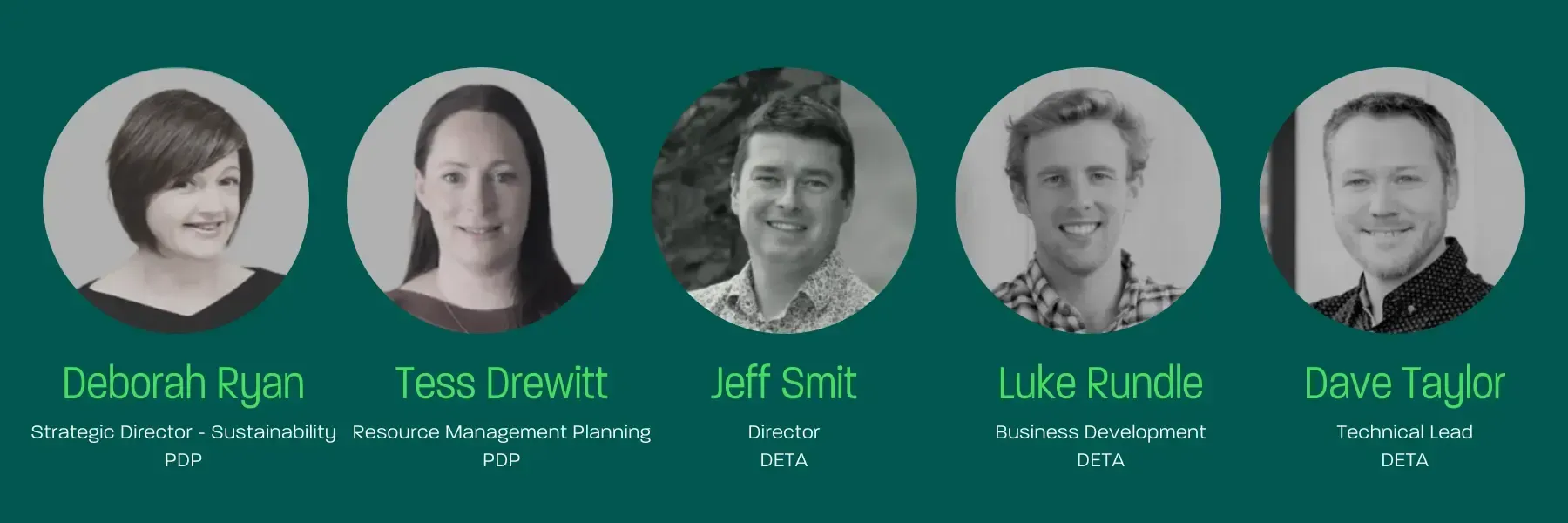

We’ve got your back with an on-demand webinar - Industrial Process Heat Consents. This isn’t just another compliance talk — it’s a practical, down-to-earth guide to help you get to grips with the latest updates to the RMA. We’ve brought together a panel of experts from the consenting and engineering fields who break down the changes in a way that’s easy to digest. They cover everything from the nitty-gritty details of what’s new to how you can streamline your consenting process and avoid any pitfalls along the way.

But the best part is that it’s not just about ticking boxes. The changes to the RMA actually present a golden opportunity for your business to step up, cut emissions, and even save on energy costs. Our webinar is here to show you how to turn these challenges into wins for your business.

Understanding the RMA and its impact on your business

The RMA has been shaping New Zealand’s environmental policies since 1991, and it’s a big deal — especially if your business relies on natural resources like land, water, or air. Think of the RMA as New Zealand’s playbook for sustainable management. It’s the legislation that makes sure we’re looking after our environment while balancing economic activities, and that’s no small task.

But here’s where it gets tricky - the RMA isn’t just a one-size-fits-all law. It’s a living document that’s constantly being updated to meet new environmental challenges. And right now, it’s undergoing some significant changes, particularly around how we manage industrial process heat devices. If your business uses boilers or other fossil fuel-powered systems, these updates are something you definitely need to stay on top of.

So, what’s changing? For starters, the government is cracking down on greenhouse gas (GHG) emissions from industrial process heat. The changes mean that new low-medium temperature coal boilers are completely banned, and existing ones will need to be phased out by 2037. Plus, if your boiler emits more than 500 tons of CO₂ per year, you’re going to need a resource consent — and that’s not just a tick-the-box exercise. Your consent application will now need to include an emissions reduction plan, with clear, actionable targets. This includes all boilers – natural gas, LPG, diesel as well as coal.

These changes are happening fast. The new rules already apply to any new boilers, and for existing systems, the deadline to have your consents in place is January 26, 2025. Meeting these deadlines is essential for compliance, but it also opens the door to future-proofing your business, lowering emissions, and uncovering potential cost and energy savings.

Top takeaways from our expert panel

When you register for our free on-demand webinar, Industrial Process Heat Consents, you'll gain a better understanding of the changes to the RMA and some valuable insights.

What does it all mean?

The changes to the RMA are a shift in how businesses must approach their process heat devices. Our panel unpacked the implications of these changes, emphasising the importance of understanding the new requirements and how they impact both new and existing operations.

What do you need to know?

Being informed is crucial whether you’re managing consent internally or relying on external experts. Our experts highlighted the essential details you need to grasp, from the necessity of emissions reduction plans to the importance of considering long-term fuel supply options. The panel provided actionable advice on navigating these requirements effectively to ensure your business stays compliant and operates efficiently.

Who needs to be involved?

Successfully adapting to these changes isn’t a solo effort. It requires collaboration across different areas of your business, from environmental compliance teams to operational managers. The panel discussed the roles that need to be engaged and when to bring in external expertise to optimise the consenting process and ensure your business is prepared for the future.

With gas availability in New Zealand facing challenges and prices expected to rise, it's also important to consider future fuel supply forecasts when selecting and consenting process heat devices. Planning ahead now can help mitigate risks and ensure long-term sustainability.

Preparing for the future - take action now

The recent changes to the RMA bring new challenges, but they also offer opportunities to enhance your business’s compliance, efficiency, and

sustainability services.

Our expert panel broke down the key changes, highlighted what you need to know, and discussed who should be involved in your compliance strategy. They also touched on the broader implications, like the future of fuel supply in New Zealand and how it could impact your choices.

Don’t miss out on this valuable information. The insights shared in our on-demand webinar, Industrial Process Heat Consents, are essential for anyone navigating these changes.

Register for our FREE on-demand webinar.