Hospital Retires Coal Boilers for Health

Strategic Planning, Options Feasibility Study, Concept Design and Business Case Development project, led by DETA – SCDHB Timaru, New Zealand

Even before the New Zealand Government mandated carbon neutrality (under the Carbon Neutral Government Programme) – the Facilities team at Timaru Hospital were committed to replacing the 1970’s vintage coal boilers with a low carbon alternative. All the hospital’s process heat requirements were supplied by the boilers, needing more than 2,000 tonnes of coal per year, leading to carbon emissions of more than 4,500 tCO2-e.

Commissioning DETA to help, the hospital team was focused on looking for ways to improve its environmental footprint, eliminate coal emissions, and put in-place reliable, efficient infrastructure for the future to meet the hospital’s heating, hot water, and steam sterilisation requirements. It was clear from the start that one of the paramount project success factors was to maintain health services to the 60,000 people served by the DHB, through any transition works and into the future. Another key challenge was matching available technologies to the varying process heat requirements (steam for sterilisation and cooking, domestic hot water and heating hot water for radiators and theatres).

Starting with an Options Study, DETA quickly identified that:

- The existing system suffered from significant inefficiencies leading to much greater carbon emissions than necessary. As much as 50% of the energy delivered to site from coal was lost through non optimised combustion and system losses.

- The aged, centralised steam generation and distribution system posed risks in terms of maintaining services, and increased costs of both energy and maintenance.

- The removal of steam and some level of decentralisation would be necessary to deliver the desired outcomes.

After a thorough review of potential technologies, initially the DETA feasibility options study landed on biomass, hot-water boilers to replace the coal-fired steam boilers, primarily due to the high temperature water required for heating (especially for the operating theatres) and the scarcity of suitable, commercial heat-pump options. However, continued collaborative investigations and changing technology meant that an air-sourced heat pump option became realistic if certain hurdles could be overcome. It was in overcoming these hurdles that collaboration, trust, and teamwork came to the fore. The most significant change was to deal to Operating Theatre heating with a stand-alone solution, so removing a potential roadblock. This still left air-source heat pumps to deliver most of the other heat requirements; needing careful design and selection to deliver even on the coldest days. The biomass and heat-pump options were developed in tandem to ensure a workable and cost-effective solution could be presented to the DHB.

“It is a cliché but being part of the Timaru hospital decarbonisation mission was a classic ‘think outside the box’ project,” says Mark Davis, DETA Optimisation Team Lead, “At first it seemed as if the hurdles of meeting the hospital’s requirements were too much for a heat-pump solution. But our teams took the time to ask, “what If’ and “why not”. Not only did a heat-pump turn out to be the most cost-effective solution, but it also delivered unexpected benefits to the hospital.”

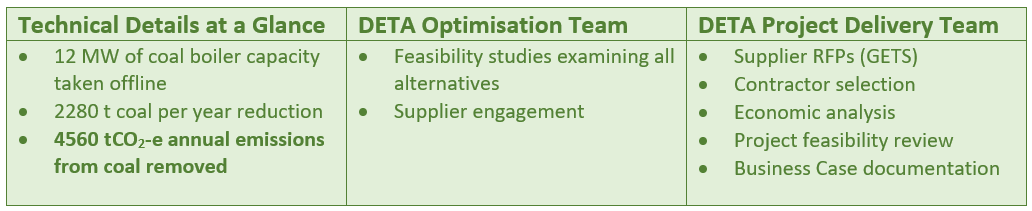

The DETA Optimisation Team worked closely with the hospital team and contractors to meet the project’s technical challenges. Meanwhile DETA’s Project Delivery Team brought workflow management, contracting and procurement expertise, assisting the DHB to put in place the structures and specifications needed for a successful outcome. With DETA’s assistance, the DHB were able to present a strong business case which was used to secure over $4M of funding for the selected option.

“The case for change was strong, and we worked closely with the Timaru team to focus in on two viable options which we could then develop the detailed business case for”, says Jon Bruce, Project Delivery Team Lead at DETA. “We had to not only be sure that the technical and economic outlooks were robust, but also that the project could be delivered in such a way that interruption to any hospital activities were minimised – this would be essential to the project’s overall success.”

The selected supplier for the main works was Christchurch-based, HVAC specialists Airtech, who brought a similar teamwork and collaboration mindset aimed at delivering the best outcome for the client. A great example of this was that a complete transition of the operating theatres over to the new, improved services was undertaken in only 4 days, minimising as far as possible any disruption to the busy theatre schedules.

The new systems are now installed and operational. Some of the additional and unexpected benefits for the hospital have been,

- Improved stand-by capacity for critical services (e.g., operating theatres)

- Greater flexibility to cope with peak demands

- A significant decrease in total energy used on-site

- Improved futureproofing for an evolving health system

- Siting the new system on the hospital roof has maintained real estate for future development and expansion if required

DETA are leading the way with numerous heat-pump projects across New Zealand. As well as working with public sector organisations, DETA have experience across dairy, meat, wood, and food processing sites. In this project the creative magic was achieved with all parties taking a collaborative approach and being prepared to test their thinking. The result is that Timaru Hospital now have a robust, future-proofed system that is more efficient, has reduced waste, and is able to flex and adapt to the changing needs of the hospital departments. Best of all, when we visited recently to see the finished system (on a typical Timaru frosty morning), the hospital was warm, whilst the old boiler house was cold and silent with not a coal truck in sight.