DETA & ANZCO Food's 1st EECA GIDI Decarbonisation Initiative Completed

EECA GIDI project, HTHP Concept Design & Installation project, led by DETA – ANZCO Foods Canterbury, New Zealand

DETA has partnered with ANZCO Foods for more than 10 years to support the company in its mission to become the world’s most environmentally responsible red meat producer. The latest step in this journey has been focusing on decarbonisation, specifically, reducing coal usage at ANZCO’s largest site through the installation of an industrial high temperature heat pump (HTHP).

HTHPs are a relatively recent addition to the decarbonisation toolbox. They can be used to capture heat from other plant systems, such as condensing refrigerant, that is otherwise discharged to the atmosphere, and transfer that heat to raise the temperature of water flows around site. This means that instead of using coal to heat water you can use electricity instead.

Since the HTHPs can take advantage of some clever engineering and New Zealand’s low-carbon electricity grid, energy efficiency improvements of between 300% to 500% can often be achieved.

At ANZCO’s largest site, DETA was engaged to use this fantastic efficiency and identify how a HTHP could be implemented, how it could be integrated into a brownfield site and how this would all work with minimal impact on production. To support the implementation DETA connected ANZCO with the Energy Efficiency and Conservation Authorities’ (EECA) Government Investment in Decarbonising Industry (GIDI) fund.

The EECA GIDI fund alignments included:

- a focus on decarbonising process heat;

- help for businesses to install low emission, high efficiency equipment;

- achieving valuable carbon emission savings aligning with New Zealand’s pathway for long-term climate targets.

Early in 2021, GIDI project funding approval was successfully awarded to ANZCO Foods, and the project got the green light. DETA got straight into doing what they do best: turning the concept into a reality. This involved:

- Project management – day to day management of contractors, tracking schedule, budget, variations and ensuring overall quality of outputs

- Civil construction design and build – to ensure the new equipment was housed appropriately and other minor civil works to ensure the building’s footprint could be accommodated on site

- Electrical supply upgrade – adding a 1MVA transformer to ensure sufficient capacity for the new equipment

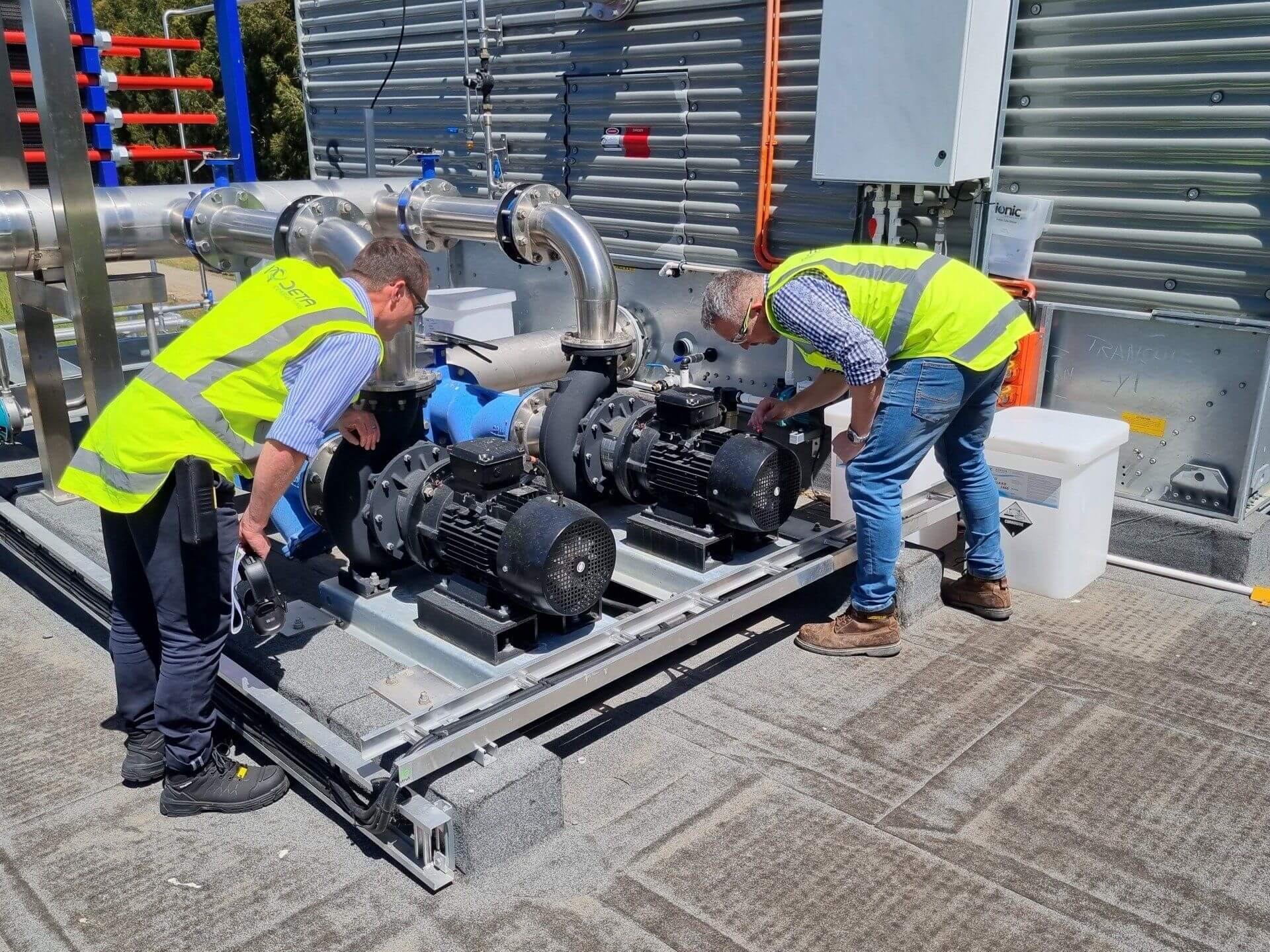

- Mechanical – mechanical installation of the HTHP into the new building envelope and taking advantage of the existing heat discharge to enable HTHP operation

- Site integration – mechanical works to integrate the water flows in and out of the new HTHP

- Commissioning – ensuring systems performance was achieved and that a good handover of information and operational guidance was communicated between the installation contractors and site personnel.

The milestone of completing system commissioning, and therefore commencement of HTHP operation, allowed this project to achieve the distinguishing characteristic as the first operational GIDI-supported project – this meant that the carbon reduction journey of EECA's GIDI fund had now begun.

The DETA project delivery team worked alongside ANZCO’s project sponsor, John Corcoran, Group Infrastructure and Asset Manager, as well as a host of other key contributors from within the ANZCO business. DETA developed strong relationship with a variety of contractors all of whom were fundamental in the success of this project Active Refrigeration, Bradfords, SWARM Intelligence along with key enabling contributions from the teams at Electricity Ashburton and Ashburton District Council.

This project was an example of how our business can lead the way in sustainability and decarbonisation,” says John Corcoran. “At ANZCO, building relationships is at the heart of our operation, seeing the project team overcome some of the challenges that were identified during this project’s delivery is a testament to how we can work collaboratively with our project managers and contractors, to deliver real change.

The project delivery phase ran through the 2021 COVID outbreak and experienced some quite inclement local weather conditions during the construction phase. Additionally, installing a system on a working site means that commissioning always has its fair share of surprises and nuances, but the collaboration and communication between all parties allowed to project to successfully overcome these.

“We have a significant amount of experience at ANZCO’s Canterbury site within the DETA team and we used every ounce of this to ensure a successfully delivered project in line with ANZCO’s key project success criteria and also EECA’s project milestones,” says Jon Bruce, Senior Project Manager at DETA Consulting. “Every project has its hic-ups, but I’m proud to say that we navigated through any issues in close partnership with ANZCO, and our contractors, toward a successful result.”

Part of EECA’s requirements is to verify the projected carbon savings with continuous measurements following the commissioning phase. “The calculations are quite data-heavy, but it was great to track the reduction in overall site coal use”, said Luke Rundle, Commissioning Lead at DETA Consulting.

Working together with so many contractors to really help push New Zealand on its decarbonisation journey was what was most rewarding,” Hamish Hendry, Project Engineer at DETA Consulting.

“We’re now looking across the ANZCO group to see which other sites could benefit from integration of a HTHP, and other innovative technology options,” reflect John Corcoran. “I enjoyed collaborating alongside the DETA team who were instrumental in ensuring the success of the project overall. We’ll use this experience to generate future success within our business, to ensure the ongoing work on our sustainability and decarbonisation journey continues.”

The overall result was that ANZCO Foods now has a proven and robust way of supplying process heat to their plants that significantly reduces emissions without compromising quality, cost and reliability drivers.

DETA is leading the way with numerous heat-pump projects across Australasia helping the dairy, meat, wood, and the public sector on their decarbonisation journey. DETA develops concepts through a real-world lens, constructs robust business cases for capital approval, manages all aspects of the project delivery and then supports the commissioning of the solution to ensure best bang for buck.